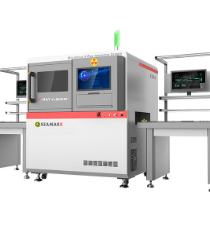

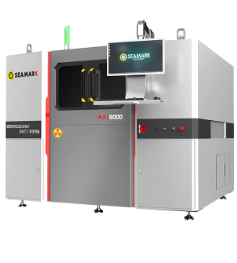

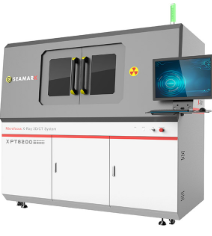

Our state-of-the-art X-ray inspection machines provide unparalleled accuracy and safety inspections. It can realize various detection methods such as 2D/3D/CT and is suitable for quality inspection, three-dimensional measurement and non-destructive analysis. Not only that, we can also customize 3D X-ray inspection equipment according to customer needs.

As an advanced technical means, X-ray inspection equipment has a very wide range of applications, covering many industries and fields.

In the aerospace field, X-ray inspection equipment can be used to detect internal defects in key components such as aircraft engine blades and turbine disks to ensure flight safety. By conducting detailed internal structural analysis of these components, potential cracks, wear or other problems can be discovered, and repairs or replacements can be made in time to avoid accidents.

In the field of automobile manufacturing, X-ray inspection equipment can be used to detect the sealing and integrity of key parts such as automobile braking systems and fuel systems to improve the safety performance of automobiles.

In the field of electronics and electrical appliances, X-ray inspection equipment can be used to detect the welding quality and internal structure of circuit boards, semiconductor devices, etc., to ensure the stable operation of electronic products. Through precise internal structure analysis of these components, potential soldering, short circuits or other problems can be discovered, and repairs or replacements can be made in a timely manner to avoid failures in electronic products.

The above are only some of the application scenarios of X-ray inspection equipment. In fact, X-ray inspection equipment may be used wherever there is a need for inspection. This kind of equipment plays an irreplaceable role in many fields with its advantages of high precision, non-contact, fast and efficient.

With the rapid development of science and technology, electronic components are used more and more widely. From mobile phones and computers to cars and airplanes, they are all inseparable from the support of electronic components. However, these tiny components are often hidden inside the product, making it difficult to directly observe their status and quality. At this time, a detection technology that can penetrate the object and reveal the internal structure is needed - X-ray detection equipment.

X-rays are electromagnetic waves with extremely short wavelength and high energy that can penetrate most materials. When X-rays pass through an object, the degree of absorption of the X-rays will also be different due to the different densities of the objects. Therefore, by receiving and analyzing the transmitted X-rays, an image of the internal structure of the object can be obtained. This is the basic principle of X-ray inspection equipment.

In the production and testing process of electronic components, X-ray inspection equipment plays an important role. It can detect defects inside components, such as cracks, voids, impurities, etc., thereby ensuring product quality and reliability. In addition, X-ray detection equipment can also be used to study the microstructure and properties of materials, providing strong support for the research and development of new materials.

Overall, X-ray inspection equipment reveals to us the inner world of electronic components, allowing us to better understand and control the quality of our products. In the future, with the continuous advancement of technology, X-ray inspection equipment will play a greater role in more fields.

In today's highly competitive market environment, companies need to continuously innovate and improve to meet the increasingly diverse needs of customers. To this end, we have launched customized 3D X-ray inspection equipment services to provide enterprises with more accurate and efficient inspection solutions.

This kind of service is designed and produced according to the specific needs and application scenarios of the enterprise, and has the advantages of strong pertinence, high efficiency, low cost and good after-sales service. We will serve you wholeheartedly and provide you with the most suitable X-ray inspection equipment solutions to help you improve product quality and production efficiency.

By in-depth understanding of the company's production process, product characteristics and inspection objectives, we can tailor the most suitable X-ray inspection equipment for the company. This kind of equipment can improve detection efficiency and accuracy, reduce misjudgments and missed detections, thereby improving the production efficiency of enterprises.

As an important non-destructive testing technology, X-ray inspection equipment has many unique advantages and a wide range of application fields. First of all, X-ray inspection equipment has high precision and sensitivity and can detect tiny defects and anomalies, which is crucial to ensuring product quality and safety. Secondly, X-ray inspection equipment can achieve non-contact inspection without causing any damage to the object being inspected, which is particularly important for the inspection of some fragile items or precision equipment.

In addition, X-ray inspection equipment is also fast and efficient, and can complete a large number of inspection tasks in a short time, greatly improving production efficiency. At the same time, X-ray inspection equipment can also be combined with other inspection technologies to achieve more comprehensive inspection and analysis.

In practical applications, X-ray detection equipment is widely used in aerospace, automobile manufacturing, electronic and electrical appliances, petrochemical industry, metallurgical mining and other fields. For example, in the field of aerospace, X-ray inspection equipment can be used to detect internal defects in key components such as aircraft engine blades and turbine disks; in the field of automobile manufacturing, X-ray inspection equipment can be used to detect key parts such as automobile braking systems and fuel systems. The sealing and integrity; in the field of electronic and electrical appliances, X-ray inspection equipment can be used to detect the welding quality and internal structure of circuit boards, semiconductor devices, etc.

In general, X-ray inspection equipment plays an irreplaceable role in many fields with its advantages of high precision, non-contact, fast and efficient. With the continuous development of science and technology, X-ray inspection equipment will continue to be improved and innovated, bringing more convenience and value to mankind.

Shenzhen Zhuomao Technology Co., Ltd. (also known as “SEAMARK ZM”) is a national-level well-known high-tech and "Little Giant" enterprise integrating R&D, production and sales in Shenzhen.

Zhuomao Technology has been focusing on intelligent inspection and intelligent soldering equipment for 18 years, specializing in providing advanced intelligent X-Ray inspection equipment, X-Ray counting machine, 3D X-ray equipment, BGA rework station, automatic tin removal equipment, automatic re-balling machine, laser soldering equipment, non-standard automation equipment and other overall solutions for electronics manufacturing, 3C products, industrial precision castings, semiconductors and other industries.

As a pioneer in the field of inspection and rework of China's electronic intelligent equipment industry, its main products have dominated the market segment for many years!

Our X-ray non-destructive testing equipment, with its advanced imaging technology, can thoroughly inspect materials without causing any damage, ensuring reliable results to maintain quality and comply with strict industry standards.

This equipment is suitable for X-ray inspection of winding process batteries in the lithium battery industry. It has flat-panel detector imaging technology and can expand advanced detection functions such as pole piece wrinkles and pole piece folding.

Our X-ray Counting System, tailored for the lithium battery industry, employs advanced flat-panel detector imaging to precisely detect defects like pole piece wrinkles and folding, ensuring unparalleled efficiency and reliability in inspection processes.

Our Industrial Microfocus X-Ray 3D/CT Equipment combines cutting-edge microfocus technology with 3D/CT capabilities for precise inspection and analysis of complex industrial components, enhancing efficiency and accuracy across various sectors.

Our 3D inspection technology utilizes advanced Japan X-ray imaging to provide precise analysis of product components, enabling thorough quality assessments and ensuring compliance with industry standards.

Our equipment can detect a wide range of defects including voids, cracks, inclusions, and dimensional variations, offering comprehensive defect analysis for diverse manufacturing applications.

Yes, our flexible X-ray inspection systems can be seamlessly integrated into existing production lines, adapting to different layouts and configurations to optimize inspection efficiency.

Absolutely, our systems offer real-time imaging and analysis capabilities, enabling immediate feedback on production quality and facilitating timely adjustments to ensure product integrity.

By enabling early detection of defects and minimizing the need for manual inspection, our technology helps reduce production downtime, scrap rates, and rework costs, ultimately enhancing operational efficiency and profitability.

2024 © Shenzhen Zhuomao Technology Co., Ltd Privacy policy