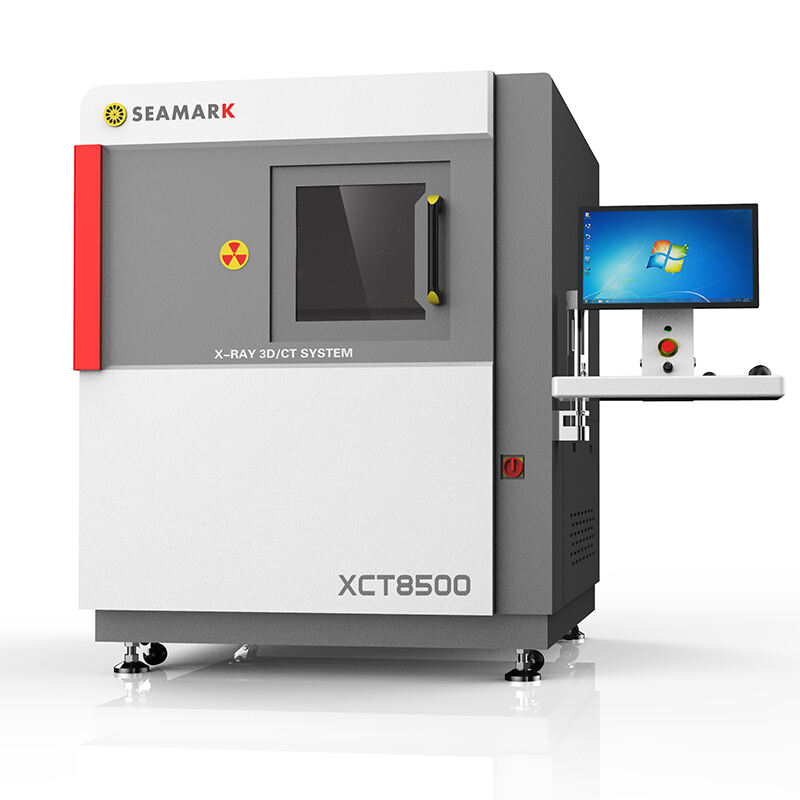

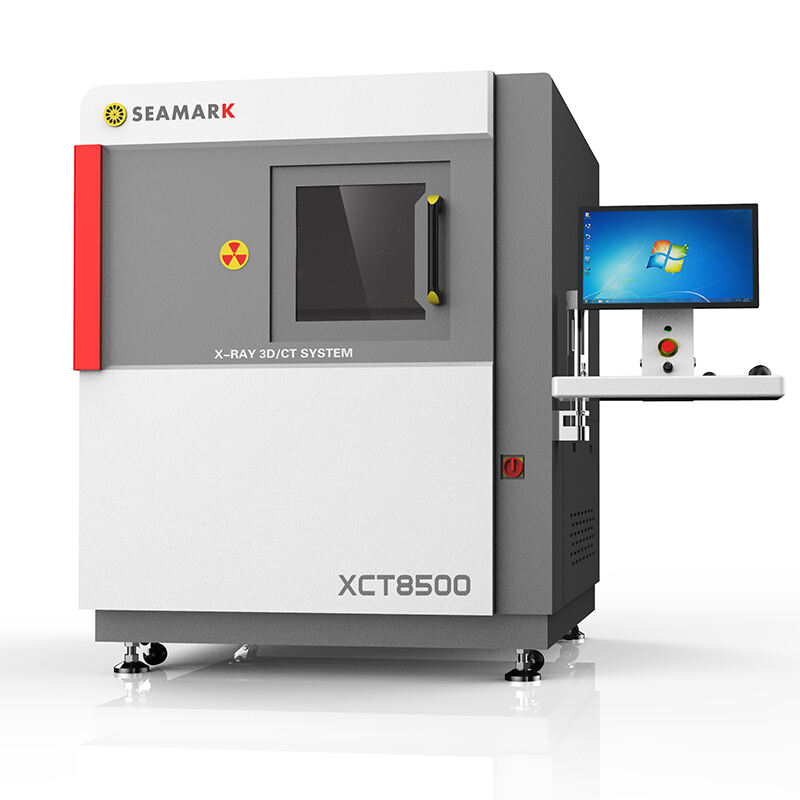

XCT8500 adopts COMET open ray tube design, with defect detection capability up to 0.5μm. It can implement 2D/3D/CT and other inspection methods, and is suitable for quality inspection, three-dimensional measurement and non-destructive analysis. It is suitable for product inspection of PCB boards, chips, IGBT modules, sensors, fuses, components, plastic parts, ceramics, biomaterials, small cast parts and aluminum castings. 3D X-ray inspection equipment can also be customized according to customer needs.

XCT8500 adopts YXLON X-ray tube design, the defectdetection ability can reach 0.5μm. It can realize 2D/3D/CT andother detection methods, and is suitable for quality inspection,three-dimensional measurement and non- destructive analysis.

●With planar CT function (PCT), it can be used for 3D/CT inspection of printed circuit boards, SMT, IGBT, wafers, etc.

●With cone beam CT function, it can be used for detection of sensors, relays, micro motors, materials, and aluminum castings

●Convenient 360° fixed-point observation mode

●2D bubble detection software module (optional)

●3D measurement and analysis software module (optional)

X-Ray Tube Parameters

Tube Type | open micro-focus transmisslon X-ray source |

Tube Voltage Range | 20-160KV |

Tube Current Range | 0.01mA ~ 1.0mA |

Maximum Tube Power | 64W |

Maximum Target Powerr | 15W |

Minimum Object Distance (FOD) | 300 um |

Micro Focus Size | < 1 um |

Minimum Defect Detection Capability | < 500 nm |

Flat Panel Detector Parameters

Flat Panel Type | Amorphous silicon flat panel detector (optional) |

Pixel Matrix | 1536x1536 |

Field of View | 130mmx130mm |

Resolution | 5.8Lp/mm |

lmage Frame Rate (1x1) | 20fps |

AD Conversion Digits | 16bits |

3D/CT Parameters (Optional Function)

CT Scan Cycle | 20s |

CT Reconstruction Time | 30s |

2024 © Shenzhen Zhuomao Technology Co., Ltd Privacy policy