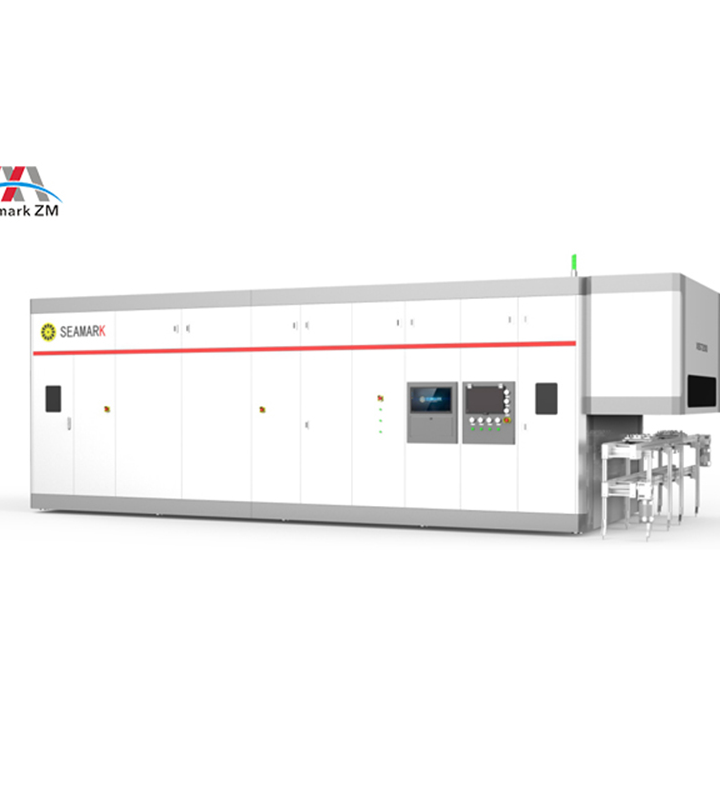

Our cutting-edge X-ray inspection system is tailored for the lithium battery industry, specifically designed for detecting stacked (laminate) battery cells. Utilizing TDI line scanning technology, it offers unparalleled precision and efficiency. With customizable features catering to various client requirements, including fold detection in electrode sheets and cell folding, our system ensures superior quality control throughout the manufacturing process. Ideal for B2B customers seeking advanced solutions for battery production quality assurance.

Our battery X-ray inspection equipment adopts the most advanced flat-panel detector imaging technology and has high-precision and high-efficiency inspection capabilities.

The system can not only expand multiple detection functions such as pole piece wrinkles and pole piece folding, but can also achieve seamless connection with upstream and downstream logistics lines to achieve fully automated detection and processing of battery products.

The intelligent design of the system enables it to be customized according to the specific needs of customers, thereby meeting their production needs to the greatest extent.

Our goal is to provide customers with reliable solutions to help them improve production efficiency and product quality, and achieve long-term and stable business growth.

Our fully automatic X-ray inspection system for cylindrical batteries is an efficient inspection solution specially designed for all types of cylindrical batteries. The system is connected to the upstream and downstream logistics lines to achieve fully automatic online detection, automatic sorting of NG products, and automatic output of OK products to the logistics line and into downstream equipment.

Not only that, we also provide optional automatic reflow soldering retest function to further improve product quality and production efficiency. The system's intelligent design and high degree of automation provide stable and reliable support for the operation of the production line, helping customers reduce costs and increase production capacity.

The system of our equipment is specially designed for digital soft-pack batteries and uses the latest flat-panel detector imaging technology to achieve efficient online fully automatic detection.

The system is connected to pallet palletizing and loading, and can automatically pick up and put it into the equipment for inspection, thus saving human resources and time costs. At the same time, the system also has the function of automatically sorting NG products and automatically taking out OK products, which improves the operating efficiency of the production line.

In addition, the system can also code and stack materials on blister boxes, making product traceability and management more convenient. Customers can customize according to their own production needs to ensure the efficiency and accuracy of product testing while improving the overall efficiency of the production line.

We are committed to providing our customers with fully customized battery X-ray inspection solutions to meet their unique product inspection needs. Not only can our systems accommodate various battery types such as digital pouch, cylindrical, button, energy storage/power coiled and aluminum case batteries, they can also be customized to meet our customers' specific needs.

Our fully automated online inspection system can ensure the stable improvement of product quality, efficient operation of the production line, and comprehensive monitoring and management of the production process. No matter what our customers' needs are, we can provide flexible and reliable solutions to help their businesses continue to grow.

Shenzhen Zhuomao Technology Co., Ltd. (also known as “SEAMARK ZM”) is a national-level well-known high-tech and "Little Giant" enterprise integrating R&D, production and sales in Shenzhen.

Zhuomao Technology has been focusing on intelligent inspection and intelligent soldering equipment for 18 years, specializing in providing advanced intelligent X-Ray inspection equipment, X-Ray counting machine, 3D X-ray equipment, BGA rework station, automatic tin removal equipment, automatic re-balling machine, laser soldering equipment, non-standard automation equipment and other overall solutions for electronics manufacturing, 3C products, industrial precision castings, semiconductors and other industries.

As a pioneer in the field of inspection and rework of China's electronic intelligent equipment industry, its main products have dominated the market segment for many years!

Our X-ray non-destructive testing equipment, with its advanced imaging technology, can thoroughly inspect materials without causing any damage, ensuring reliable results to maintain quality and comply with strict industry standards.

This equipment is suitable for X-ray inspection of winding process batteries in the lithium battery industry. It has flat-panel detector imaging technology and can expand advanced detection functions such as pole piece wrinkles and pole piece folding.

Our X-ray Counting System, tailored for the lithium battery industry, employs advanced flat-panel detector imaging to precisely detect defects like pole piece wrinkles and folding, ensuring unparalleled efficiency and reliability in inspection processes.

Our Industrial Microfocus X-Ray 3D/CT Equipment combines cutting-edge microfocus technology with 3D/CT capabilities for precise inspection and analysis of complex industrial components, enhancing efficiency and accuracy across various sectors.

This device is designed for the lithium battery industry, specifically for the detection of battery cells using the stacking (blading) process.

It utilizes TDI (Time Delay Integration) line scanning technology for high-quality imaging.

It can be expanded to detect features such as electrode wrinkling and electrode folding.

Yes, it can be tailored to accommodate the X-ray testing needs of customers based on their specific battery testing requirements.

This device provides superior imaging quality and customizable detection features specifically tailored to the needs of the lithium battery industry, ensuring accurate and reliable testing results.

2024 © Shenzhen Zhuomao Technology Co., Ltd Privacy policy