The online PCB QR code recognition and testing equipment supports teaching and import and export functions for various product testing, automatic loading, automatic detection and judgment, and automatic sorting of good and defective products. The rail-type transmission system, large inspection area, and new digital flat-panel detector can be connected to the SMT production line for high-capacity automatic online full inspection. X-ray inspection equipment can be customized according to customer needs.

Product Description:

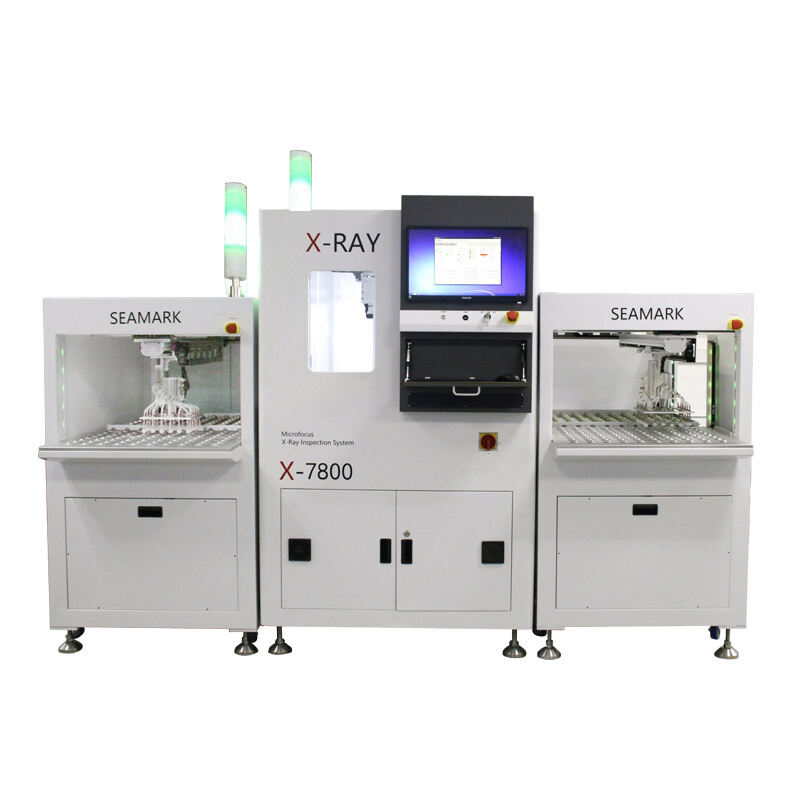

The Fully Automatic PCB Board Inspection Equipment Drilling Offset & QR Code Recognition X-7800 is an advanced solution designed for precision inspection of Printed Circuit Boards (PCBs) in modern electronics manufacturing. This equipment combines the latest drilling offset correction technology with QR code recognition, providing comprehensive inspection capabilities for PCB boards.

The X-7800 is fully automatic, eliminating the need for manual intervention and ensuring consistent inspection quality. It boasts a high-precision drilling offset correction system that accurately identifies and corrects any drilling errors, ensuring precise hole placement and improving production yield.

In addition to drilling offset correction, the X-7800 also features QR code recognition technology. This technology enables operators to quickly scan and read QR codes on PCB boards, accurately capturing relevant information such as board specifications, component placements, and testing parameters. This significantly improves workflow efficiency and reduces the potential for human error.

The equipment's compact and modular design allows for easy integration into existing PCB manufacturing lines. It offers a user-friendly interface and comes with comprehensive training materials, ensuring smooth operation and minimal downtime.

The Fully Automatic PCB Board Inspection Equipment Drilling Offset & QR Code Recognition X-7800 is the perfect choice for electronics manufacturers seeking to improve PCB inspection accuracy, efficiency, and reliability.

Applications:

The Fully Automatic PCB Board Inspection Equipment Drilling Offset & QR Code Recognition X-7800 is suitable for a wide range of applications in the electronics manufacturing industry, including:

With its advanced technology and comprehensive inspection capabilities, the Fully Automatic PCB Board Inspection Equipment Drilling Offset & QR Code Recognition X-7800 is an essential tool for electronics manufacturers seeking to improve PCB inspection accuracy, efficiency, and reliability.

Key Features:

2024 © Shenzhen Zhuomao Technology Co., Ltd Privacy policy