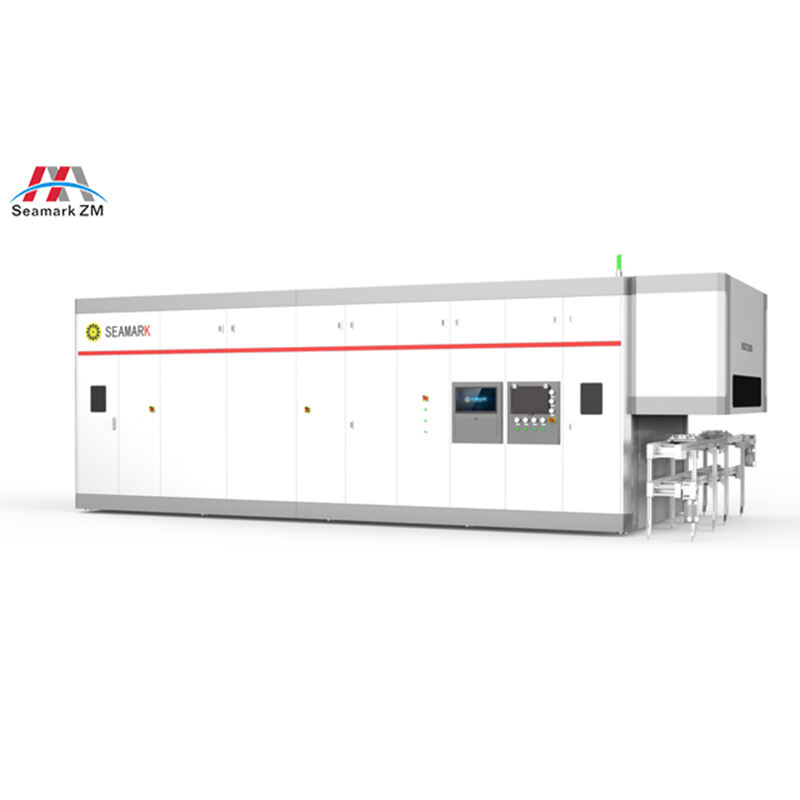

This equipment realizes online fully automatic detection of multi-layer laminated power batteries, connects with the upstream and downstream logistics lines, realizes automatic removal of battery cells, puts them into the equipment for inspection, automatically sorts NG products, automatically takes out OK products, and outputs them to the logistics line, entering the downstream equipment. Battery X-ray inspection equipment can be customized according to customer needs.

XB7200 achieves fully automatic inline inspection of multi-layer stacking power batteries, using TDI line scanning image technology or using area array image acquisition technology. The inspection contents include: weighing, angle overhang, large folds, tab creases, etc.

Technical Parameter

Size | 8500mm*3200mm*2800mm |

Beat | ≥24PPM and above (2 or 4 comers) |

Exoellence Rate | ≥99.5% |

Weighing | Measurement Accuracy ≤ 0 01g, Weighing ≥ 5kg |

Equipment Failure Rate (OT) | ≤2% |

Overkill Rate | ≤1.5% |

Missed Kill Rate | ≤0% |

Incoming Method | logistics line |

Radiation Safety Standards | ≤1μSVV/hr |

Receiver | Linear Array Camera TDl or Flat Panel Detector |

X-Ray Tube Parameters

Tube woltage Range | 40-90KV/40-130KV |

Tube Current Range | 10-200UA/10-300UA |

Inspection Efficiency and Accuracy Parameters | |

Inspection Accuracy | 15μm |

Repetitive Testing Accuracy | ±30μm |

Other Parameters

Change Time | The change time for old varieties is ≤ 2hours per person;The replacement time for new varieties is ≤4 hours per person. |

Compatible Ranges | Compatible Ranges: Square aluminum shell: Length:80-220mm;Wdth:1 30 -200mm; Thickness:10-25mm.Blade Battery:Length 320-600mm; Wath: 80-120mm; Thickness:10-30mm |

Testing Content | weighing, angle super hang, large areaWVrinkles, ear creases, etc. |

2024 © Shenzhen Zhuomao Technology Co., Ltd Privacy policy