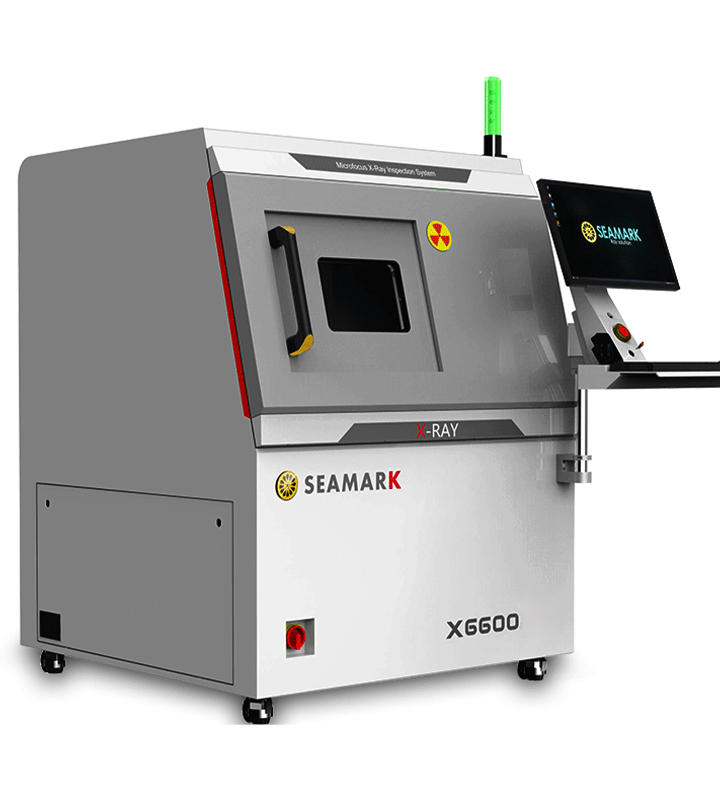

Our X-ray inspection machine is an advanced non-destructive testing equipment designed to provide efficient and accurate internal structure analysis.

It is widely used in various industries including aerospace, automotive manufacturing, electronics and more to ensure product quality and safety. Here are some of the key features and benefits of our X-ray inspection machines:

High-resolution imaging: Using the latest X-ray imaging technology, capable of capturing tiny internal defects and inconsistencies

User-friendly interface: The intuitive operation interface makes it easy for operators to get started even without in-depth technical background.

Automated features: Reduce human error and improve inspection consistency and repeatability.

Customizable solutions: We design and adapt the functionality of our machines to meet the specific needs of our customers to meet specific application requirements.

Our X-ray inspection machines are an indispensable tool in your quality assurance process, helping you improve product quality and ensuring your customers receive the safest, most reliable products.

We understand that each customer has unique needs, so we provide customized services to meet various testing requirements. Whether it's products with special dimensions or applications with specific testing standards, our team can provide professional advice and reliable solutions.

Upon purchasing our X-ray inspection machines, customers will also enjoy comprehensive technical support and premium customer service. Our service team is ready to respond to customer inquiries and needs at any time, providing prompt and effective assistance to ensure that customers can make the most of our equipment

In the contemporary tight production process, time is money. Our X-ray inspection machine is designed based on this concept, capable of achieving high efficiency in detection speed while ensuring quality. With the latest rapid processing algorithms and sensitive sensors, it can almost instantly complete the capture and analysis of images, ensuring that products on the production line can be continuously inspected without causing any bottlenecks. By using our equipment, businesses can not only significantly improve production efficiency but also maintain a leading position in the competitive market.

Precision is paramount in non-destructive testing, and our X-ray inspection machine is equipped with cutting-edge high-resolution imaging systems, delivering the most accurate scan results available on the market.

Whether examining the internal structures of minute components or identifying concealed defects in large castings, our equipment effortlessly accomplishes these tasks.

It not only showcases product interiors with exceptional detail but also facilitates quantifiable analysis of detected flaws through advanced image processing software, aiding businesses in enhancing product quality and reducing defect rates during production processes.

We understand the importance of safety in industrial inspection, which is why we have incorporated numerous safety features into our X-ray inspection machine design.

From the robust and durable construction of the machine body to protective measures that comply with international safety standards, every detail is aimed at ensuring the safety of operators.

The equipment is equipped with lead shielding to effectively prevent radiation leakage, while emergency stop buttons can immediately cut off power to the equipment in critical moments, ensuring that operators are not harmed.

Through these rigorous safety measures, our equipment provides operators with a safe and reliable working environment.

Shenzhen Zhuomao Technology Co., Ltd. (also known as “SEAMARK ZM”) is a national-level well-known high-tech and "Little Giant" enterprise integrating R&D, production and sales in Shenzhen.

Zhuomao Technology has been focusing on intelligent inspection and intelligent soldering equipment for 18 years, specializing in providing advanced intelligent X-Ray inspection equipment, X-Ray counting machine, 3D X-ray equipment, BGA rework station, automatic tin removal equipment, automatic re-balling machine, laser soldering equipment, non-standard automation equipment and other overall solutions for electronics manufacturing, 3C products, industrial precision castings, semiconductors and other industries.

As a pioneer in the field of inspection and rework of China's electronic intelligent equipment industry, its main products have dominated the market segment for many years!

Our X-ray non-destructive testing equipment, with its advanced imaging technology, can thoroughly inspect materials without causing any damage, ensuring reliable results to maintain quality and comply with strict industry standards.

This equipment is suitable for X-ray inspection of winding process batteries in the lithium battery industry. It has flat-panel detector imaging technology and can expand advanced detection functions such as pole piece wrinkles and pole piece folding.

Our X-ray Counting System, tailored for the lithium battery industry, employs advanced flat-panel detector imaging to precisely detect defects like pole piece wrinkles and folding, ensuring unparalleled efficiency and reliability in inspection processes.

Our Industrial Microfocus X-Ray 3D/CT Equipment combines cutting-edge microfocus technology with 3D/CT capabilities for precise inspection and analysis of complex industrial components, enhancing efficiency and accuracy across various sectors.

Our multi-layer stack power battery testing equipment offers fully automated detection capabilities. It seamlessly integrates with upstream and downstream logistics lines, facilitating automatic extraction of battery cells, conducting comprehensive testing, sorting NG (Not Good) products automatically, and retrieving OK products for further processing downstream.

By implementing our online automated testing solution, battery manufacturers experience significant improvements in efficiency and quality control. With real-time detection and sorting capabilities, potential issues are swiftly identified and addressed, minimizing production downtime and ensuring only high-quality batteries proceed through the manufacturing process, thereby enhancing overall productivity and customer satisfaction.

Absolutely. Our battery X-ray inspection equipment is highly adaptable and can be tailored according to the specific needs and preferences of our clients. Whether it's adjusting parameters, adding features, or modifying functionalities, we ensure a solution that precisely fits your demands.

Our system employs advanced automation technologies to swiftly differentiate between NG (Not Good) and OK battery products. Through precise detection mechanisms, NG items are promptly segregated, ensuring only superior quality batteries proceed down the logistics line for further processing, while any defective units are efficiently managed.

Our equipment provides seamless integration with both upstream and downstream logistics lines. Through sophisticated interfacing capabilities, it facilitates the automatic transfer of battery cells for testing, efficient sorting of products, and smooth transition of OK items for downstream processing, ensuring a streamlined workflow.

2024 © Shenzhen Zhuomao Technology Co., Ltd Privacy policy